|

| |

|

| |

|

Developing practical techniques aimed at restoration of the basin ecosystem

and environment.

|

| |

|

|

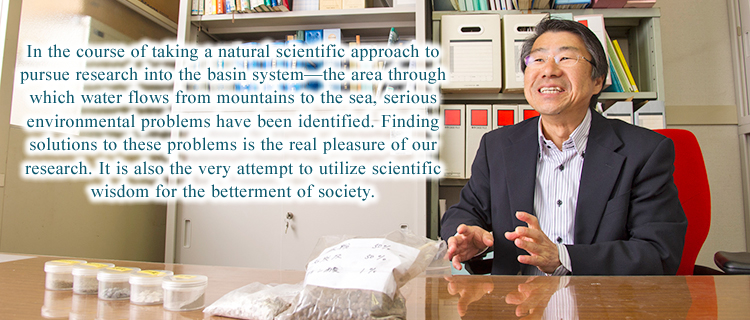

Through research into the basin system, Professor Tamiji

Yamamoto has analyzed material cycles and devised many effective measures to

improve deteriorated conditions of aquatic environments so far. His research

is not confined to conventional research just understanding the present

situations, but is characterized by developing remediation technologies for

problem-resolution which is linking to contributions to the local

community.

“The term ‘basin system’ refers to the area through which water flows from

mountains through rivers and flows into the sea. Since the water carries a

variety of substances before reaching the sea, river mouth areas tends to

most contaminated. Particularly, organic matter accumulates on the coastal

seabed forming organically enriched sediments” explains Professor Yamamoto.

|

|

| |

What is the present state of the ocean? According to the

professor, although the seawater has been getting clear, bottom sediments

are contaminated with organic matter. This is thanks to the efforts over

more than three decades continued by the Ministry of the Environment to

regulate the total loads of pollutants. Water pollution, red tide caused by

eutrophication, and other issues that were once sources of great concern

have now largely been remedied, allowing us to bring back the beautiful sea.

Nevertheless, Professor Yamamoto points out that there are still other

problems to be addressed.

“It is true that the seawater has become clean, but which means that less

food available for marine organisms, making them difficult to grow. This

situation must be improved.”

|

|

|

Toward this end, Professor Yamamoto has taken two

approaches. One is to improve the quality of the organically enriched

sediments, and the other is to supplement insufficient nutrients in the

sea.

He says, “The sediments are inherently difficult to pass through air, and a

highly toxic substance called ‘hydrogen sulfide’ can be generated in the

sediments under an anaerobic condition. Hydrogen sulfide smells like rotten

eggs, which you can often perceive around places such as gutters or ditches.

Due to this fatal substance, worms, bivalves, and other living organisms

that are served as foods for fish have become unable to live in the sea

bottom. For this reason, I first wanted to remediate organically enriched

sediments.” |

|

| |

|

Utilizing industrial byproducts, by recycling oyster shells, slag, and coal

ash

|

| |

|

|

Thus, Professor Yamamoto developed various materials for

sediment improvement.

One of them is oyster shells. Hiroshima Prefecture is producing the largest

amount of oysters in Japan. When crushed oyster shells are dried with hot

air at a temperature of 400℃ or so, calcium carbonate of the shell surface

turns into calcium oxide. One you plow the calcium oxide-bearing materials

into the tidal flat sediments, hydrogen sulfide will be neutralized.

Another improvement material uses coal ash, which is a powdered byproduct

produced from coal-fueled power plants. By adding cement, coal ash is

granulated. We can apply the granulated coal ash to remediate sediments. The

granulated coal ash has many minute spaces/pores between the grains.

Accordingly, if mixed with granulated coal ash, sediments are oxidized due

to the large amount of air contained in the ash, soon suppressing the level

of hydrogen sulfide as well. Professor Yamamoto says, “Granulated coal ash’s

ability to reduce the concentration of hydrogen sulfide is about ten times

higher than that of oyster shells.” |

|

| |

Professor Yamamoto also developed remediation materials using

several types of slag, a byproduct from the steelmaking process. One of

these is blast-furnace slag, which is remnant after iron ore is burned at a

high temperature of 1,500℃. Though looking like sand, blast-furnace slag has

the property of hardening with water. Another example is dephosphorization

slag, produced by removing phosphorus from iron. Dephosphorization slag is

generated when high purity steel is made from iron. For either type of slag,

the iron content plays an important role. Iron ions dissolve in water and

combine with hydrogen sulfide, so as to produce iron sulfide. As a result,

the material is able to reduce the level of hydrogen sulfide.

All the sediment improvement materials mentioned above are in line with the

move to promote more effective use of recycled byproducts that are produced

in large quantity during industrial processes, based on the Basic Law for

Establishing a Recycling-based Society enacted in 2000. For their usefulness

and ecological features, these materials have attracted much attention from

many companies, local governments, and national agencies and ministries.

|

|

|

|

| |

|

Hoping to develop more remediation materials that will be further embraced

by society: the next theme is underground spring water

|

| |

|

According to research themes, study locations vary greatly, including

mountains, lakes, the ocean, and ports. His team pursues aggressive

research to explore the mysteries of nature.

|

|

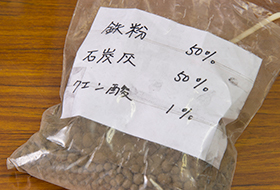

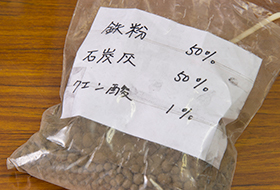

Professor Yamamoto says, “Now we are working to develop another

material for sediment improvement.” This material consists of iron powder,

coal ash, and citric acid. Its main component, iron, is reliable in

controlling hydrogen sulfide, and coal ash contains nitrogen. By combining

these two components, this material can not only reduce the level of

hydrogen sulfide, but also supply nitrogen and phosphorus, which comprise

major nutrients which nourish aquatic living things. This is exactly a novel

material designed to remediate organically enriched sediments while

supplementing insufficient nutrients in the sea, so as to increase the

amount of food for marine organisms. Citric acid is a chelating agent to

dissolve iron in water.

“In fact, some people have a feeling of resistance about slag, because it

carries a negative image as industrial waste. However, this newly developed

material is free from such worries. Our experiment conducted in the tidal

flats in Onomichi proved that in the site where this material is mixed with

the sediments showed nine times magnitudes higher in the number of Japanese

short-necked clams (Asari) compared to the number in the site without mixing

this material. I myself was a little surprised by the experimental results.”

He added that, based on these results, this research project was

subsequently granted research funds provided by the Ministry of Agriculture,

Forestry and Fisheries, and that his team is scheduled to implement a series

of experiments in earnest in this and the next academic years.

“I am greatly delighted that my research is capable of making a contribution

to the local community. Since various countries around the world share

similar environmental problems, I expect that our research findings will

eventually find broader applications,” he says with a smile.

Professor Yamamoto also stated that he will place further emphasis on

research into underground spring water on the sea bottom. “Regarding

so-called underground spring water, we still do not clearly understand the

flow rate volume and kinds of water quality there, regarding the contents of

nitrogen, phosphorus, iron, etc. We aren’t sure yet whether the underground

spring water may impose a burden on the sea, or if it may help in cleaning

seawater, so I want to conduct more detailed investigations.” |

|

| |

| Tamiji Yamamoto |

|

Professor

Laboratory of Aquatic Ecosystem Management

Department of Environmental Dynamics and Management

April 1, 2004 – present Professor, Hiroshima University

August 1, 1995 – March 31, 2004 Associate Professor, Hiroshima

University

April 1, 1991 - July 31, 1995 Assistant Professor, Hiroshima

University

April 1, 1985 - March 31, 1991 Scientist, Aichi Fisheries

Institute

April 1, 1983 - March 31, 1985 Research Fellow, Japan Society for the

Promotion of Science

Posted on Jun 2, 2014

|

| |