|

| |

|

| |

| Research in low-temperature food processing technologies to avoid wasteful, dangerous and unhygienic situations is underway. |

| |

|

|

Food engineering is a field of applied science that aims towards the efficient processing and storage of food products. In the Japanese food industry, the preparation of raw materials and the processing and manufacturing processes are becoming more mechanized, and it seems that there are no major issues. However, according to the experts, there is still room for improvement.

Professor Hagura is renowned as a topnotch researcher in the field of food engineering. Low-temperature food processing is one of his best-known areas of research. His work started with a photograph that he saw in a magazine of a frozen tuna processing site. Viewing the sight of frozen tuna being cut with an electric saw, Professor Hagura felt “This wastes the parts left over after cutting! It’s dangerous for people to apply a blade to tuna! The workplace is unhygienic!” He commenced his research trying to think of a way to improve the situation.

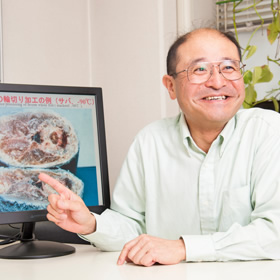

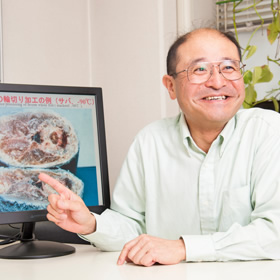

Firstly, he applied frost shattering as a method of cutting without using a saw. This uses the embrittlement phenomenon, whereby matter becomes brittle and easy to break when at low temperature. Assuming a clean cut like when chalk breaks, initially he used mackerel in an experiment of cutting rounds. |

|

| |

Professor Hagura says, “Prior to the experiment I thought of a simple method of breaking, and first expressed this in a mathematical formula. I mathematically analyzed the load, and made a small cut into the section that I want to break. I found that this leads to accurate breaking.”

Next they tried filleting, and succeeded in filleting (processing in vertical sections) using fracture load. Moreover, the recovery ratio improved by frost shattering and separating the head and leftover flesh on the spine that are left over when filleting, developing a new way to utilize marine resources that were never before attempted. Professor Hagura says “Muscle is used for fish mince, collagen is extracted from the skin and sinews, and we can recover fish oil and calcium from the bones.” |

| |

| Low-temperature processing is technology that controls materials at the appropriate temperature. Its applications are extended even further. |

| |

Frost shattering has many benefits. Ingredients with high levels of water or fat and oil can also be easily shattered, and as heat generation is prevented, processing can be conducted while protecting the nutrients that are heat-sensitive, as well as preventing unpleasant odors.

As explained in the fish example mentioned above, tissue segmentation is also possible. “Our ultimate goal is to be able to use resources with no waste. In current distribution processes, food products are frozen in the area they are produced, then defrosted and processed, then frozen again and transported to the supermarket shelves. There is repetitive freezing, and this actually leads to deterioration of the food. We want to develop a style where there is freezing only once,” says Professor Hagura. |

|

|

|

| |

In addition to fish, Professor Hagura is also conducting research on how to cleanly remove the shell from crabs and mantis shrimps, and receives numerous offers for joint research.

In the process of such research, after repeating the process of measuring the embrittlement temperature, the next thing that Professor Hagura thought of was ‘a method of nondestructive measurement of the structure and state of food using electric properties.’

“We can actually find the temperature of embrittlement by conducting a breakdown test. This research started from the perspective of reducing waste, so it’s pointless as is. So I started this research to see if there’s a way to look at the internal state of food without breaking it.”

The research targets are food oils, rice, tofu, yoghurt, chocolate, curry roux, etc. The work on efficient management of oil by measuring the degree of deterioration of the oil in a fryer is particular interesting.

The measurement instrument used was developed jointly with a private company, and is already almost at the stage where it can be merchandized as a product. “It’s called ‘Rekka-Meel’. When you put it in a fryer, it continues to record data. Eventually we intend to connect it to a POS system, to enable monitoring of the level of deterioration of the oil at store outlets by headquarters. I want it to be used on fryers throughout Japan.” |

| |

| Research results put to use in foods around us. This is rewarding. |

| |

‘Rekka-Meel’

oil deterioration measurement device

| |

“There are not very many food engineering research labs in Japan. The fields covered are extremely broad, ranging from the chemical engineering to physical properties and rheology. What’s more, we deal with content that has been derived from other research, so we gain insights on various public issues, and the research extends even further,” says Professor Hagura.

Oysters too, known as a specialty of Hiroshima, are a subject of Professor Hagura’s research. Oysters are generally enjoyed in winter, but Professor Hagura’s research revealed that the flavor of oysters peaks in the spring. “The good flavor of oysters is comprised of amino acid and glycogen. We came to this result by measuring their content over a period of two years. We are also researching frozen oysters. If there is greater knowledge of the appropriate method to freeze and store high quality oysters around April when the flavor is best, as well as the appropriate method to defrost them, people will be able to enjoy oysters all year round, which will also lead to greater demand.”

Professor Hagura says that his starting point as a researcher of food engineering was that he likes to eat. He will surely continue researching even more extensively as someone supporting Japan’s food culture. |

|

| |

| Yoshio Hagura |

| Professor, Hiroshima University Graduate School, Food Engineering

Graduated from Tokyo University of Fisheries, School of Fisheries, Food Engineering, 1985

Completed Masters Degree Program, Tokyo University of Fisheries, School of Fisheries Graduate School, 1988

Completed Doctoral Degree Program, Tokyo University of Fisheries, School of Fisheries Graduate School, 1991

Assistant, Hiroshima University, April 1, 1991 – March 31, 1997

Associate Professor, Hiroshima University, April 1, 1997 – March 31, 2007

Professor, Hiroshima University, April 1, 2007 –

Posted on Feb 25, 2013 |

| |