From understanding microorganisms to efficient bioproduction

from various feedstock

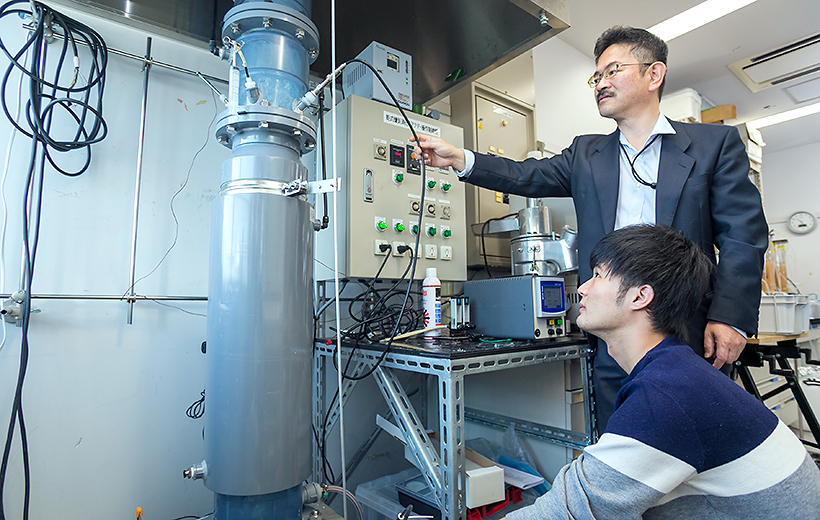

Professor Nakashimada specializes in fermentation technology. He explores useful microorganisms, sheds light into the metabolism occurring within microbial cells or between microorganisms and conducts basic research on the methods of controlling the functionality of these microorganisms. Based on these studies, he has proposed several energy-generating and useful material production processes using microorganisms.

He is working on two major research projects: research in biomass utilization technology and gas fermentation technology for carbon-recycling.

■Biomass Utilization Technology

Professor Nakashimada has developed some processes involving methane fermentation for utilizing “biomass” that includes plant-based organic resources such as food residues, livestock manure, woody biomass, and unconventional organic wastes containing high nitrogen or salinity. Methane is the main component of natural gas. Biogas containing methane produced via methane fermentation can be an alternative energy source to natural gas. Indeed, methane can be generated from organic resources through hydrothermal treatment. However, his laboratory has been conducting research on a biotechnology-based process utilizing accumulated knowledge on fermentation technology derived from traditional sake brewing to advanced bioengineering. For a successful biological process, he believes the feasible process formulation in addition to understanding and manipulation of target microorganisms helps achieving the bioengineering goals.

“We have been consistently paying attention to organic resources for years as they come into focus. We have tried to convert “biomass” to energy fuel. Even if carbon dioxide (CO2) is emitted from biomass-derived fuels after combustion, it is fixed by plants. This way, CO2 is recycled again and again, making carbon neutrality possible.”

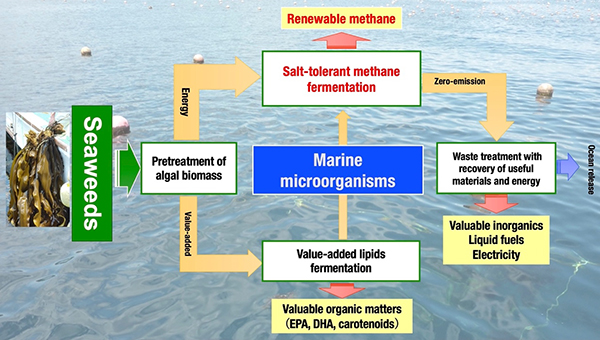

Fig. 1: Development of key technologies for complete utilization of macro algae as energy and material resources facilitated by the unique metabolism of marine microorganisms.

Fig. 1: Development of key technologies for complete utilization of macro algae as energy and material resources facilitated by the unique metabolism of marine microorganisms.

Methane is known as a more potent greenhouse gas than carbon dioxide. Thus, biogas production and its use via methane fermentation will lead to mitigation of global warming because it reduces methane gas otherwise naturally released into the atmosphere if it is produced through the decomposition of organic waste and other processes.

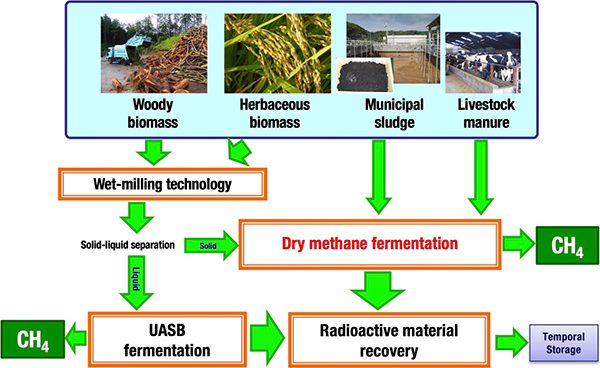

Professor Nakashimada’s research team has discovered that microbial consortia of marine origin exhibit high methanogenic activity derived from acetic acid in a hypersaline environment. They have successfully developed highly efficient technologies for converting macro algae (seaweeds), such as kelp and sea lettuce, into energy and fuel resources (Fig. 1). Moreover, they are also working on the establishment of biotechnology and the designing of a system that use methane fermentation technology in reducing the volume of plant biomass contaminated with radioactive materials released from the Fukushima Daiichi Nuclear Power Plant (Fig. 2).

Fig. 2: Volume reduction and conversion into biomass energy of biomass from areas known to be contaminated with radioactive materials.

Fig. 2: Volume reduction and conversion into biomass energy of biomass from areas known to be contaminated with radioactive materials.

Potentials of microorganisms for the development of

direct carbon-recycling technology

Japanese Prime Minister Yoshihide Suga stated that Japan would aim to achieve carbon neutrality by 2050 during his policy speech in October 2020. The measures devised towards that goal include carbon recycling. Carbon recycling is intended to reduce CO2 emissions by collecting and reusing CO2 in the air as well as those stored in carbon reservoirs.

In addition to the research on biological methane production from biomass, Professor Nakashimada’s research team has long been developing biotechnology to use CO2 directly for carbon recycling. In the early 2000s, they discovered the bacterial strain HUC22-1, which produces acetic acid and ethanol from H2-CO2, and characterized its ethanol production pathway for the first time.

- * The research results of Professor Nakashimada were recognized with the prestigious Encouragement Award from the Society for Biotechnology, Japan (Terui Award) in 2006.

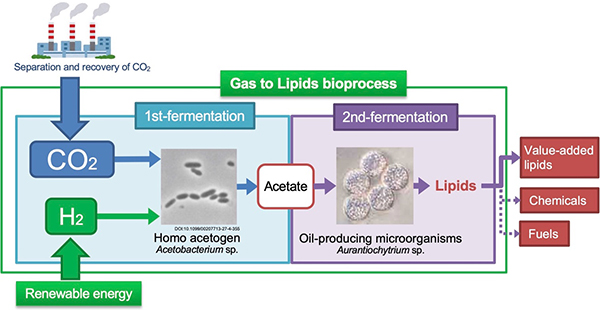

Moreover, he has launched the project “Development of a Gas-to-Lipids Bioprocess” with Professor Tsunehiro Aki and the Chugoku Electric Power Co. Ltd. supported by the New Energy and Industrial Technology Development Organization (NEDO).

The research is so named because the aim is to produce useful lipids from CO2 and H2 using a two-stage fermentation through the action of two microorganisms. At the first stage, a homoacetogen, Acetobacterium woodii ferments CO2 and H2 into acetic acid, and then, Aurantiochytrium consumes acetic acid and stores hydrocarbons including carotenoids and useful lipids such as long-chain saturated fatty acids and highly unsaturated fatty acids. The produced lipids can be used as raw materials for a wide range of products such as cosmetics, health food, chemicals, and fuel.

The demonstration plant is currently under construction at a carbon-recycling research site located in Osaki-Kamijima Island, Hiroshima Prefecture and is planned to be tested by the end of 2023.

Fig. 3: A conceptual scheme of gas-to-lipid bioprocess

Fig. 3: A conceptual scheme of gas-to-lipid bioprocess

Synthetic Gas Fermentation Technology for Carbon Recycling

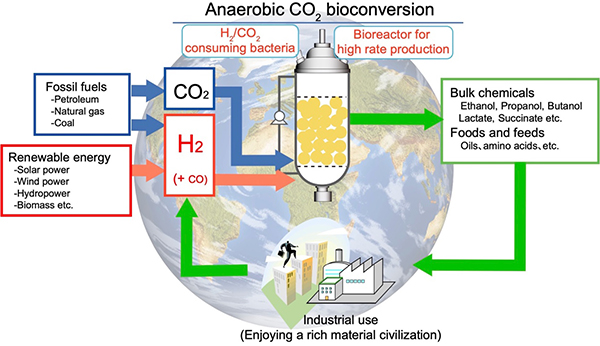

Our civilized society depends on enormous amount of energy generated from fossil resources which will, however, be certainly depleted in the near future. In this regard, concerns have been raised that there will be shortages not only of energy but also of raw materials for chemical products used to build many everyday items. To overcome the problem, the professor believes that CO2 should serve as raw materials for manufacturing after the depletion of fossil resources.

The concept can be used for increasing the value of renewable methane obtained by the above-mentioned methane fermentation. It is difficult to use methane directly as fermentation feedstock. However, if methane is configured into synthetic gas (mixture of H2/CO/CO2), a type of microorganism can consume the synthetic gas as well as H2 and CO2. The professor says “thus, I selected homoacetogens such as Acetobacterium and Moorella as “gas converters” because I want to produce chemicals from both organic feedstock via synthetic gas including biomass, renewable methane and used plastics, and CO2 using renewable low cost H2 in the future.” They have addressed the challenge of using genetic recombination and genome engineering for the creation of microorganisms that produce targeted chemicals from synthetic gas and CO2/H2.

It is predicted that low-cost hydrogen will be available in the future, as hydrogen-based raw material can be obtained from renewable energy sources. Indeed, it has been proposed that a hydrogen-based society can be built hopefully by 2040. The professor says that “a microorganism can ferment CO2 emitted from the use of conventional energy sources, including petroleum, into useful raw materials for chemical products and food materials, using available H2 as described above.”

“The conventional industrial process was intended to make the long chains of petroleum shorter. I am confident that in the future, we will see a change in the industrial structure, which will be building materials from the minimum units of H2 and CO2. The question is, how will we be able to use biotechnology in that set-up? I am excited by this aspect of my research,” says Professor Nakashimada.

Indeed, there is a multitude of issues arising from the fact that the production rate from the created microorganism is still low for practical application and use. As a result, the size of the equipment needs to be large, thus increasing the production cost. Given these conditions, their products may become too expensive to sell.

Nonetheless, “I have a big dream for this research,” says the professor. His vision is manufacturing on Spaceship Earth.

“Chemical catalysts can produce limited materials, whereas microorganisms have the infinite potential to produce food. I can imagine the future direction of this research. For instance, assuming that a plan to build a space colony on the Moon or on Mars emerges, that we have a highly efficient technology that can produce both food and chemical products, I think such a technology will probably be used to support the plan. When I speak about Spaceship Earth, it is not all about the Earth.”

Fig. 4: Space colony = Future manufacturing on Spaceship Earth

Fig. 4: Space colony = Future manufacturing on Spaceship Earth

Professor Nakashimada vigorously conducts his research with the aforementioned vision in mind. He inspires the youth who aim to pursue a research career, as follows:

“Biotechnology is not simply meant to manipulate microorganisms. It ultimately aims to develop a technology for social implementation. This is the essence of the work at hand. Of course, science is important for me. Science discovers phenomena and technologies that turn discoveries into something useful for the people. We have been pursuing our research for about 20 years. Social trends have now aligned with our position. It has now become possible to produce something that was first considered impossible. This is therefore a very happy situation. I also believe that it is the best part of research. If you think what we are doing is somehow interesting for you, come and join us.”

Opened on August 25, 2021

Opened on August 25, 2021